Standard lab ovens and drying ovens are two types of ovens that are likely to be available to you if you ever find yourself in the market for an oven for your laboratory. There is a widespread misunderstanding that these two distinct kinds of ovens are equivalent to one another, but in reality, they are two distinct information of equipment.

About Drying Oven

It is the purpose of a drying oven to eliminate all moisture from the oven chamber in order to dry the samples in the shortest amount of time feasible. The drying oven technique involves bringing in new, dry air while simultaneously expelling the warm, wet air from the chamber. This allows for the samples to be dried very quickly. The drying and heating capabilities of an oven are brought to a high level. You will find that drying ovens are more costly than a regular laboratory oven. This is mostly due to the fact that a drying capacity, which a laboratory oven does not have, is the primary factor in the price difference. It is necessary for a drying oven to have an airflow system that is able to remove moisture from the air; yet, depending on your needs, this component may not be necessary at all. The addition of moisture, such as in steam sterilization, considerably speeds up heat penetration. Hot air ovens, incinerators, flames, radiation, and glass bead sterilizers are some of the instruments and methods that are used throughout the dry heat sterilization process.

The Dry Heat Oven Is Used In The Following Industries And Applications:

Industrial drying ovens are used in both small-batch and large-scale manufacturing settings to dry materials via the process of evaporation. Many different types of manufacturers, including those in the food processing, pharmaceuticals, agricultural, textiles, and research sectors, may use drying ovens for a variety of purposes, including the following:

- Solar cell production

- Printing using a screen

- Dried flower arrangements

- Material in the form of rolls or sheets, such as paper, foil, or film

- Fabric or textiles

- Food and related items

- Oven in the Laboratory

You can rely on Drying oven manufacturers India to provide quality throughout each and every stage of the design and production processes. They are able to produce various varieties of industrial ovens, including those that are powered by electricity, oil, or gas.

Some of the main features of

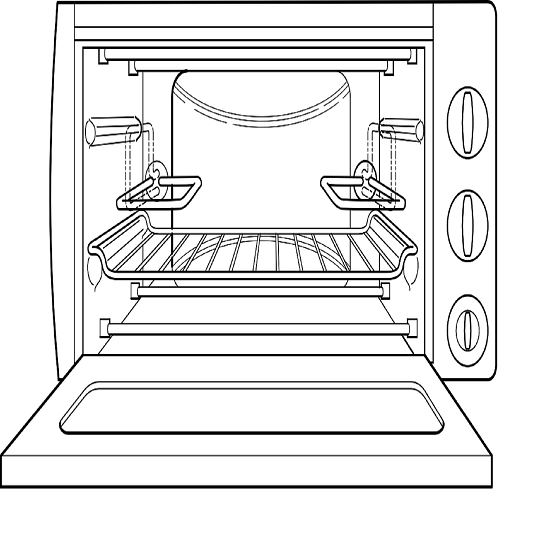

- Depending on the dry oven box size, one door or two doors may be designed for the oven.

- You will get a centrifugal wind wheel with a large diameter.

- Circulation of heat are available in a uniform manner

- The exterior is sprayed with a metallic finish and constructed of high-quality steel that was cold-rolled. Nice overall color design.

- Appropriate for all output in the workshop.

- There are three material options for the inner chamber: zinc, steel, and stainless steel.

- This product has a huge stock, can be heated up quickly, and can be used in manufacturing.

About Laboratory Oven

On the other hand, the only purpose of an oven found in a laboratory is to heat up samples. A lab oven, in contrast to a drying oven, will simply recycle the air that is already present inside the chamber. As a consequence of this, a laboratory oven will only be capable of heating. If you simply want heating capabilities, laboratory ovens are a better alternative than drying ovens since they are more cost effective and will be sufficient for the task at hand. It is probable that a lab oven will have a larger temperature range than a drying oven, so you will want to be sure that the oven you choose is able to achieve the temperatures that are necessary for your experiment.